UNDERSTANDING THE CATALYTIC CONVERTERS RECYCLING INDUSTRY

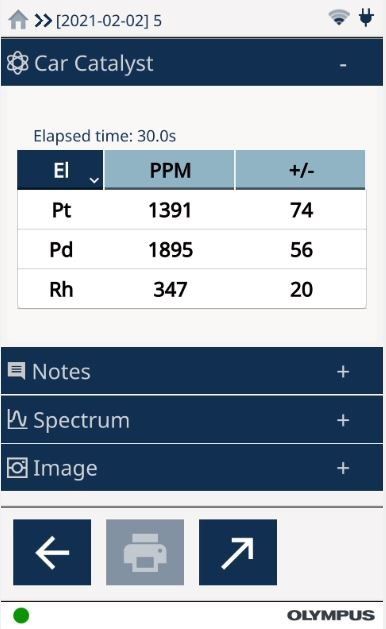

Measuring Catalytic converters with the Olympus, VANTA, handheld XRF analyser for those precious metals, such as Platinum, Palladium and Rhodium. Measuring the Catalytic converter honeycomb is an essential part of the catalytic recycling process, as the cost of the catalytic will be determined by the precious metal’s concentration. The Platinum, Palladium and Rhodium is added as a dipcoat, which is used to reduce harmful gas emissions into the atmosphere.

The increase in value for these

precious metals over the past 8 years is fuelled by demand from the automotive manufacturing industry. While South Africa holds more than 80 percent of global PGM reserves, the

catalytic recycling still plays an important role, in assuring that the reserves are not depleted in the near future. The catalytic converter recycling industry currently provides 40% of the Precious Metals used during manufacturing stages.

6 EASY STEPS FOR CATALYTIC RECYCLCING

- Upon receiving the catalytic converter, the honeycomb will be covered by a Ferrous metal. This ferrous metal usually has some value to it, as it is usually a Stainless Steel, but can also be Aluminium or Nickel. You can measure the housing with the same XRF analyser using the Alloy calibration to positively identify this material, which will generate more profit. However, this ferrous housing will have to be removed in order to get to the Precious Metals coated honeycomb.

- Once you have removed the catalytic converter honeycomb from the ferrous housing, the honeycomb will have to be crushed and prepared for XRF analysis with the Olympus VANTA.

- XRF Sample preparation can be done in many forms such as, using a Pestle and Mortar crushing bowl, electrical crushers and grinding mills and many more.

- When the Catalytic Converter honeycomb has been crushed to a fine powder, you can place some of the powder into a plastic sample cup. The sample cup is then covered with mylar film, as to ensure that the powder does not fall out of the cup, when turned upside down.

- The sample cup with the prepared sample is placed on the Olympus VANTA XRF analyser, and an XRF analysis of approx. 60seconds is performed by pressing the trigger. Something to keep in mind, when using any Handheld XRF, the longer the testing time, the better the accuracy.

- The easy-to-read results will display the elements on the left-hand side and the percentage or parts per million on the right. With these results you can accurately sort various catalytic converters with the same quantities into one bag for exporting purposes.

Why choose Olympus VANTA for Catalytic Recycling?

Using reference samples, verified by laboratories, Olympus have created a specific Catalytic converter calibration. With this catalytic converter calibration successfully being used throughout the world, you can always expect only the best precision as the calibration takes into account, most peak overlaps and the actual ceramic honeycomb matrix effects on the XRF analysis.

Copyright © 2025 - Innov-X Africa - All Rights Reserved