THE ROLE OF XRF ANALYZERS IN AUTOMOTIVE CATALYST RECYCLING

Handheld XRF analyzers play a major role in the recycling of automotive catalysts.

To understand how XRF analyzers fit into automotive catalyst recycling, it is necessary to start with a brief description of the automotive catalytic converter (also called an automotive catalyst, car catalyst, or car cat) and its function.

In short, the purpose of an automotive catalytic converter is to reduce the pollutants emitted into the atmosphere from vehicle exhaust. It does so by using a catalyst (a substrate that accelerates a chemical reaction) to turn harmful gases from the exhaust system into less polluting ones.

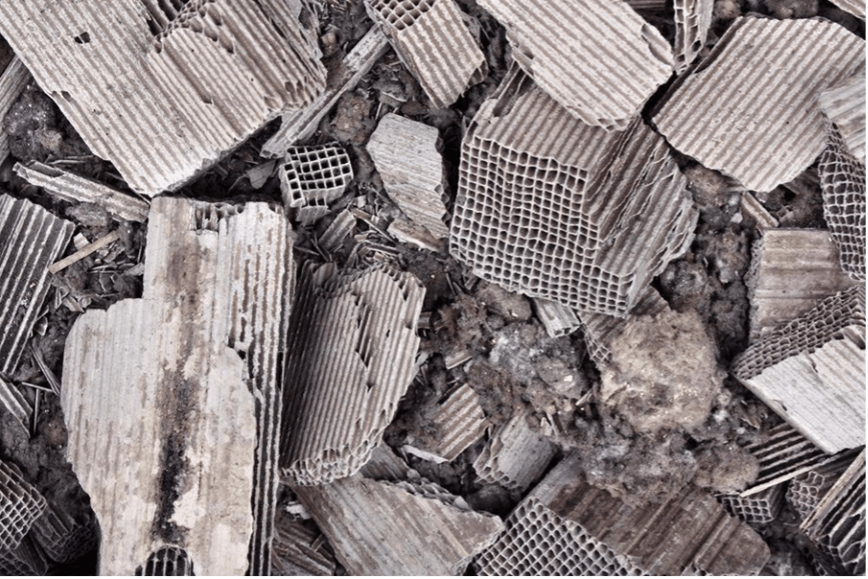

A car catalyst is a honeycomb cylinder coated with a layer of platinum (Pt), palladium (Pd), and rhodium (Rh)—also known as platinum group metals (PGMs). Unburned residues in the vehicle exhaust, such as carbon monoxide (CO), hydrocarbons (CH), or nitrogen oxides (NO), pass through the honeycomb cylinders coated with PGMs and are oxidized and neutralized by oxygen in the exhaust gas.

What’s driving the recycling of automotive catalysts?

Automotive catalysts have become an indispensable part of internal combustion engine vehicles. The average life of an automotive catalyst depends on several factors, such as fuel quality and engine cylinder volume. It usually has a service life of 100,000 km (about 62,000 miles).

With proper treatment of automotive catalysts, we can provide a second life for the PGMs in them. By properly sorting and processing spent catalysts, the PGMs can be recycled and reused in future production. Further, recycling automotive catalysts is both economically profitable and important to meet environmental standards.

Platinum and palladium are two of the most effective elements in the neutralization of noxious emissions. While platinum and palladium are used in industries besides automotive manufacturing (e.g., jewelry production), most platinum and palladium produced today are used to make automotive catalysts.

With the adoption of emission and fuel standards (China VI, Tier 3, Euro 6d, and Bharat Stage VI), the demand for PGMs will continue to grow and drive the recycling of automotive catalysts.

From the perspective of environmental protection, recycling used automotive catalysts is much less hazardous than extracting platinum group metals through mining. Further, palladium is generally a by-product of mineral processing plants, and its extraction is very inefficient.

How does handheld XRF assist in the recycling of automotive catalysts?

Without special equipment, it’s impossible to quickly determine the amount of PGMs in automotive catalysts—causing a roadblock to the PGM recovery process. This is where X-ray fluorescence (XRF) testing comes in. XRF is a proven analytical method used in the recovery of automotive catalysts.

Many recyclers rely on portable XRF devices for a fast and simple car catalyst analysis. Our

Vanta™ handheld XRF analyzer can provide the amounts of platinum, rhodium, and palladium in catalyst in seconds.

The Vanta analyzer can also analyze elements ranging from magnesium (Mg) to uranium (U) (in the order of the Periodic Table of Elements), displaying up to 45 elements. Elements of interest for the recycling of automobile catalysts include:

- Platinum (Pt)

- Palladium (Pd)

- Rhodium (Rh)

- Tantalum (Ta)

- erium (Ce)

- Selenium (Se)

- Tungsten (W)

- Silicon (Si)

- Lead (Pb)

- Zirconium (Zr)

- Ruthenium (Ru)

- Lanthanum (La)

- Nickel (Ni)

- Sulfur (S)

All these elements are prioritized and included in the Vanta analyzer’s customized car catalyst method. Of course, you can still analyze other elements from Mg to U.

Using the Vanta XRF analyzer, recyclers can categorize automotive catalysts to select an optimal extraction method for PGMs and determine a fair recovery price. The analyzer can be used in combination with grinders, blenders, and scales, making it an essential tool for recycling automotive catalysts.

The Vanta analyzer also helps prevent fraud. It detects elements that could be added to catalyst materials to falsely boost their precious metals values.

With the growth of the automotive catalyst recycling industry, the number of scammers trying to sell used automobile catalysts at the highest possible price is increasing. A common method used to falsely increase the value of automobile catalysts is adding additives containing lead (Pb). More sophisticated deception methods add tantalum (Ta) or selenium (Se) to the mixture to simulate the platinum (Pt) peak on the XRF spectrum.

Errors can also occur without malicious intent. A portable XRF device that has not been professionally calibrated can mistake tungsten (W) in diesel particulate filter (DPF) as platinum (Pt). This error is common. The Vanta analyzer can help avoid these errors and frauds thanks to its unique calibration.

How do you prepare samples from catalytic converters to get accurate and representative results?

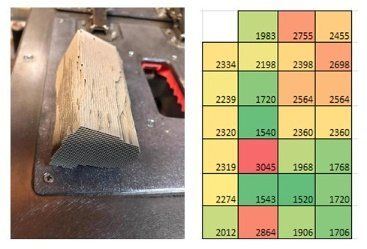

Example of a car catalyst honeycomb lump sample (left) and preliminary surface palladium (Pd) concentration (ppm) results (right) to aid in rough sorting

Sample prep is an important part of an accurate XRF analysis. When recycling automotive catalysts, two types of samples are usually prepared: honeycomb bulk samples (whole or split) and powder samples.

PGM coatings on the honeycomb structures are often not uniformly distributed. As a result, these samples can only provide a preliminary test result to classify automotive catalysts or identify "empty automotive catalysts" where the PGMs are already removed.

To classify automotive catalysts for purification or batch production, additional steps in the sample prep process are needed to obtain representative results. In general, we recommend the following method:

- Rough classification by type

- Grinding by type (it is important to make the particle size distribution as uniform as possible)

- Homogenization

- Sampling (if needed, a press can be used)

Moreover, make sure to monitor humidity closely. Fluctuation of humidity above 10% can affect the accuracy of the analysis. After sampling, it is important to take 3–5 tests and average the test results to monitor homogeneity.

Which Vanta models are ideal for car catalyst analysis?

We offer several Vanta models for recycling automotive catalysts. The models differ in three main ways:

- Analysis speed

- Sensitivity

- Ability to detect light elements, such as magnesium (Mg), aluminum (Al), silicon (Si), phosphorus (P), and sulfur (S)

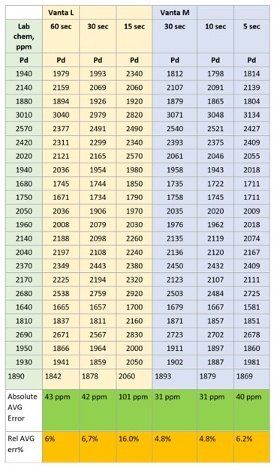

For example, the Vanta L model is a cost-effective analyzer for catalyst classification. The analyzer has a PIN detector, so it can’t detect elements lighter than titanium. The mean analysis time of the Vanta L analyzer is about 40–60 seconds.

In contrast, Vanta C and M models use a silicon drift detector (SDD) to detect lighter elements. This is helpful for determining the content of silicon carbide (SiC) and controlling for sulfur (S) content. The mean testing time of these analyzers is about 15–20 seconds—3x more efficient than the analyzers equipped with PIN detectors.

The results and errors of palladium (in ppm) in the table below show these differences. The measurement results of the Vanta M analyzer in 5 seconds are similar to those of the Vanta L analyzer in 60 seconds.

Comparison of test results and errors of palladium (Pd) between Vanta L and M analyzers showing typical precision vs. measurement time

What features on the Vanta XRF analyzer make it suited for recycling automotive catalysts?

Repeatability of results: Built with Axon Technology™ electronics, every Vanta analyzer has a high degree of repeatability, so you get the same results from instrument to instrument and test to test.

Customizable: Catalyst substrates can vary in composition in different regions depending on local emissions regulations. You can easily adapt the analyzer to different catalyst substrates using customized User Factors to improve the test accuracy.

X-ray tube options: You can choose from silver, tungsten, or rhodium anode X-ray tubes. Note that the X-ray tubes for both tungsten and silver targets are ideal for analyzing automotive catalysts. The reason rhodium tubes are not preferred is that there are corresponding characteristic peaks on the spectrum when using X-ray tubes with a rhodium target.

Large measurement window: The large window on the Vanta analyzer enables the analysis of a large surface area, improving accuracy during testing of both uncrushed cores and ground samples.

Ruggedness: Recovering catalysts is a dusty process. The IP55/54 rating for dust and moisture protection helps keep the analyzer in good working condition. Vanta analyzers are durable and include a 3-year, comprehensive warranty to keep the cost of ownership low.

XRF accessories: In production processes, the Vanta Work Station turns the Vanta analyzer into a functional benchtop XRF for a comfortable, hands-free analysis. Benchtop use is ideal for final sample analyses prior to further refining at the recycling facility or at a smelter for PGM recovery.

Supports Industry 4.0 practices: The Vanta analyzer features network connectivity and is cloud-technology enabled. XRF data can be sent directly to an ERP system without user intervention.

Light element detection:

With the rapid growth of automotive catalyst recycling, purification plants will tighten their requirements for incoming materials. The content of silicon carbide (SiC) and sulfur (S) is becoming more important when calculating the cost of incoming materials. As a result, XRF analyzers with silicon drift detectors (SDD) for light element detection will become a popular choice for car catalyst analysis.

Copyright © 2025 - Innov-X Africa - All Rights Reserved